The MS35 10018 inrush current limiting thermistor from Ametherm offers a maximum steady state current of 18A (up to +25°C) and a resistance of 10Ω ±25% (at 25°C). Ametherm’s MegaSurge™ series of inrush current limiting thermistors are capable of handling up to 900 joules of energy and 50 amperes of steady state current. These power thermistors are rugged and built to last even in the most demanding high power applications. The Ametherm MS35 devices play a key role in alternative energy applications by avoiding current spikes in the power generated by wind turbines, solar panels, and other sources as it’s fed into batteries, inverters, and other energy storage components. These MegaSurge™ devices are also used to regulate the release of battery energy in electric vehicles and in pre-charge circuits for many different types of battery chargers.

Typical applications for the MS35 series include:

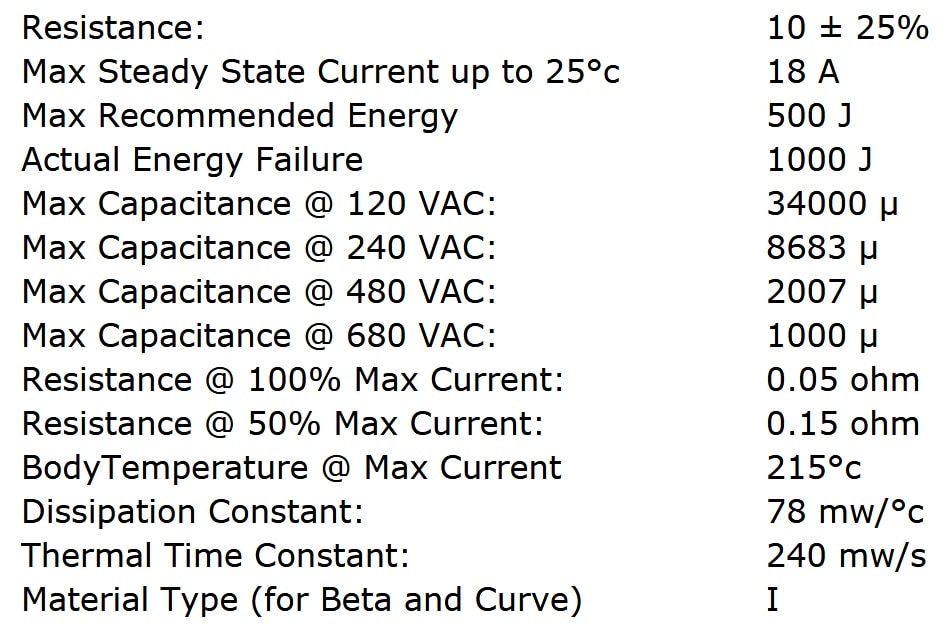

The below table gives the full specifications of the Ametherm MS35 10018 series:

| Weight | 0.00000 kg |

|---|---|

| Dimensions | 0.00 x 11.00 x 37.00mm |

| Actual Energy Failure | 1000J |

| Dissipation Constant | 78mW/°C |

| Material Type | |

| Maximum Recommended Energy | 500J |

| Maximum Steady State Current | 18A |

| Package / Size | |

| Resistance at +25°C | 10Ω |

| Series / Model | |

| Thermal Time Constant | 240mW/s |

| Tolerance | |

| Voltage Rating |

This product meets the requirements in compliance with RoHS Directive 2011/65/EU including Directive (EU) 2015/863 amending Annex II, on the restriction of the use of Certain Hazardous Substances in Electrical and Electronic Equipment.

The above product is, however, is not Pb free, using exemption 7(a) “Lead in high melting temperature type solders (i.e. lead-based alloys containing 85% by weight or more lead)“

We are pleased to provide you with a range of additional content including videos, product datasheets, case studies, white papers and application notes for your reference. Please see below for the latest content available:

| DOCUMENTATION | |

|---|---|

| Ametherm MS35 10018 MegaSurge™ inrush current limiting thermistor datasheet | |

We are pleased to provide you with a range of videos, please see below for the latest content available: