Essential Electronic Components for Medical Devices

Electronic components are crucial in medical devices, enabling accurate detection, diagnosis, and treatment of medical conditions. Selecting precise and reliable components is essential for ensuring optimal performance in medical applications.

Pressure Sensors for Medical Applications

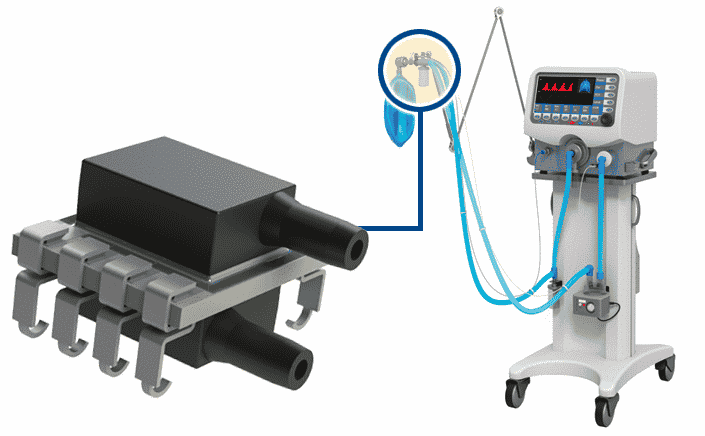

Merit Sensor LP Series - Surface mountable pressure sensors

Monitoring and controlling the amount of air, or positive airway pressure, into a patient’s lungs is critical for respiratory support. What you get with the LP Series is a sensor for very low pressures that is easy to solder to a PC board and connect to standard tubing. It is available fully compensated, saving you calibration time and equipment on the assembly line. It is also available uncompensated for lower cost. Once in the application, the LP Series performs with excellent linearity, hysteresis, and stability.

- CPAP

- Spirometers

- Ventilators

- Nebulizers

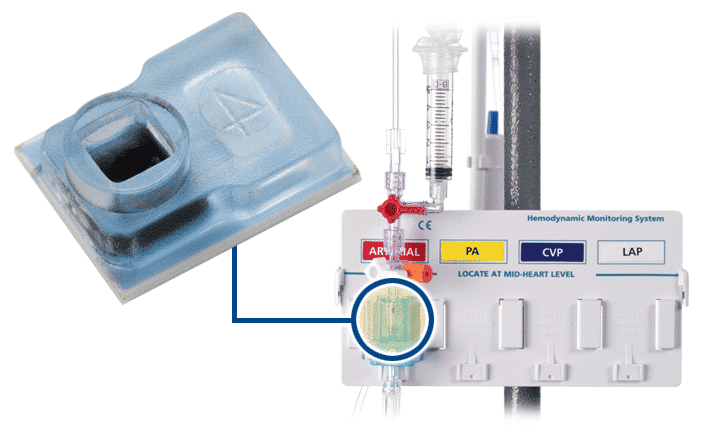

Merit Sensor BP Series - Blood-pressure transducers

Our BP Series blood pressure sensors enable continuous, reliable patient monitoring. Ideal for high-volume, low-cost applications, these AAMI-compliant sensors are customizable for other medical-grade applications.

- Invasive & disposable blood-pressure measurement

- ECMO machines

- Heart/lung machines

- Dialysis machines

- Infusion pumps

- Surgical procedures

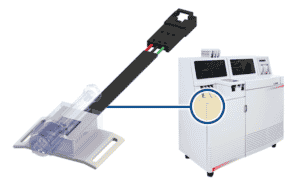

Merit Sensor MSS100 Series - Fully compensated pressure transducer

The MSS100 pressure transducer is perfect for medical, pharmaceutical, and bio-processing applications, such as blood analysis and gas chromatography. It is designed to withstand harsh liquids and vapors, providing durability and reliability. It features simple electrical connections via Molex connector and pressure connections via Luer fitting.

- Blood Analysis

- Gas Chromatography

Magnetic Sensors for Medical Applications

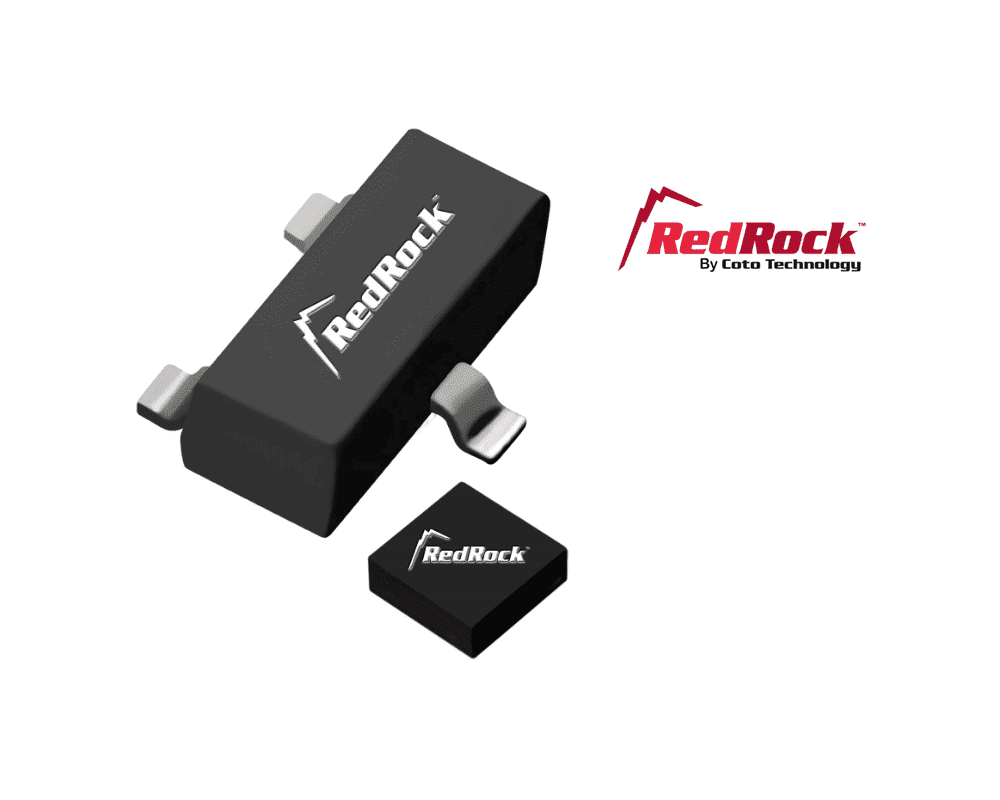

Coto Redrock TMR (Tunnel Magnetoresistance) sensors are currently the most efficient magnetic sensors available, with the lowest power consumption, highest sensitivity, and smallest packaging. These sensors are ideal for a wide range of applications, including monitoring fluid flow, liquid level, proximity, anti-tampering, and enabling “wake-up” features. As next-generation measurement and detection devices demand smaller, more sensitive, and lower power consumption sensors, Coto Redrock TMR sensors are the perfect solution for battery operated devices.

Medical Level sensing

Coto RedRock TMR (Tunnel Magnetoresistance) sensors are highly sensitive and accurate magnetic sensors, making them ideal for use in medical leveling devices. These sensors excel in precision measurement, detecting minute changes in magnetic fields to provide accurate position or orientation data, which is crucial for diagnostic equipment and patient positioning. Their non-contact measurement capability is advantageous in sterile environments, eliminating contamination risks and ensuring hygienic operation. The compact size of TMR sensors facilitates their integration into small, portable medical devices, allowing for versatile use in various medical settings, from operating rooms to patient bedsides.

Additionally, the low power consumption of TMR sensors makes them suitable for battery-operated medical devices, ensuring long battery life for portable equipment. The stability and reliability of these sensors guarantee consistent performance, which is essential for patient safety and effective medical interventions. Furthermore, TMR sensors can be seamlessly integrated with other electronic systems and software used in medical devices, enabling real-time monitoring and adjustment of levels for optimal equipment performance. These attributes—precision, non-contact capability, compactness, low power usage, stability, reliability, and integration ease—make Coto RedRock TMR sensors perfect for accurate leveling in a wide range of medical applications.

Ingestible and Implantable Devices

Hearing Aids

Magnetic sensors in hearing aids facilitate mode switching, diagnostic checks, and response tuning. As demand for smaller, more discreet hearing aids grows, these sensors play a critical role.

Insulin Pumps

Continuous-feed insulin pumps rely on magnetic sensors to detect reservoir status, ensuring seamless insulin management and avoiding complications.

Caddock Precision Resistors for Medical Applications

Caddock’s wide range of resistors, including Type MP, MV, MS, TF, USF, MK, TK, T912, T914, T1794, MG, and TG, are used in various medical applications due to their exceptional performance and reliability.

MP, MV, and MS Series Resistors

These resistors are ideal for RF power circuits, providing high accuracy and stability in demanding applications.

- RF surgical equipment

- Endoscopy equipment

- Therapeutic devices

TF, USF, MK, TK, T912, T914, and T1794 Series Resistors

Used in measurement, data acquisition, and signal amplification circuits, these resistors ensure accurate patient monitoring.

- MRI equipment

- CT scanning equipment

- Medical laboratory equipment

MP Series Resistors

These resistors serve as heaters in laboratory analysis and fluid handling equipment

- Laboratory analysis equipment

- Blood and fluid handling equipment

MG and TG Series Precision High Voltage Resistors

Used in high voltage stability and accuracy applications.

- X-ray devices

- Defibrillation devices

- Therapeutic devices

MP, SR, and CC Series Resistors

These resistors are essential for reliable motor control and accurate positioning in various medical devices.

- Patient beds

- Operating tables

- MRI equipment

- Wheelchairs, scooters, and other medical devices

Precision Capacitors for Medical Applications

SRT Microceramique Non-Magnetic NP0/X7R Capacitor Series

Non-magnetic capacitors are vital in medical applications requiring precise electrical activity measurement or stimulation. These capacitors ensure a stable power supply, precise energy delivery, and contribute to the longevity and reliability of medical devices.

- Medical simulators

- Magnetic resonance imaging

- Medical test equipment

- Laboratory analysis systems

- Implantable devices

Rhopoint Components offer high-precision Electronic Components and Sensors essential for the medical industry, including pressure sensors, magnetic sensors, resistors, and capacitors. These components ensure accurate detection, diagnosis, and treatment in medical applications.

If you have any projects related to these components, our friendly and knowledgeable engineers are here to help. Reach out to Rhopoint Components to discuss your specific requirements and find the perfect solutions for your medical device needs.