1-5V, 1-6V, 0-5V, 0-10V, 0.5-4.5V, 0.5-2.5V

A voltage output signal is an analog output signal commonly used in pressure, temperature, and other types of sensors. Within the realm of voltage output, there are a variety of I/O options, including the ones in the table below.

The most common voltage output signals, especially where power consumption is not an overriding consideration, are 1-5VDC, 1-6VDC and 0-10VDC for industrial applications.

With the growth of IoT & IIoT projects that incorporate sensors, the capability to operate from low power with less current consumption is valuable, especially for equipment being deployed in remote areas where frequent battery changes are costly and time consuming.

To address low power needs, there are a number of voltage output options that can be powered from 3V, 3.3V, 3.7V, 5V, and 9V power supplies and batteries. The voltage output signals commonly paired with these supply voltages are*: millivolt, 0.5-2.5VDC non-ratiometric and 0.5-4.5VDC ratiometric. The option for 0.5-2.5VDC output is rapidly growing in popularity because of the increased use of 3 to 5VDC lithium ion batteries.

*See table for excitation voltage requirements.

While the millivolt signal is a ratiometric signal, the term ratiometric is most commonly paired with 0.5-4.5VDC output, which is ratiometric to a regulated 5VDC excitation. The ratiometric output signal 0.5-4.5V output signal became widely popular in automotive and off-road applications. With vehicles using a 12V supply, users could regulate the voltage down to 5V, and create a signal that is proportional to the supply. A 10% reduction in supply from the 5V supply creates a proportional 10% decrease in the output signal. It is still used in similar applications and has also been utilized in industrial applications such as compressors and water pumps.

| Output Signal |

|---|

| 0-5VDC, three wire |

| 0-10VDC, three wire |

| 1-5VDC, 1-6VDC |

| 0.25 to 10VDC, 1-10VDC |

| 0.5-4.5VDC, ratiometric |

| 0.5-2.5VDC, non-ratiometric |

| Excitation Voltage |

|---|

| 10-28VDC, unregulated |

| 15-28VDC, unregulated |

| 10-28VDC, unregulated |

| 15-28VDC, unregulated |

| 5.0VDC, regulated |

| 3-5VDC, unregulated |

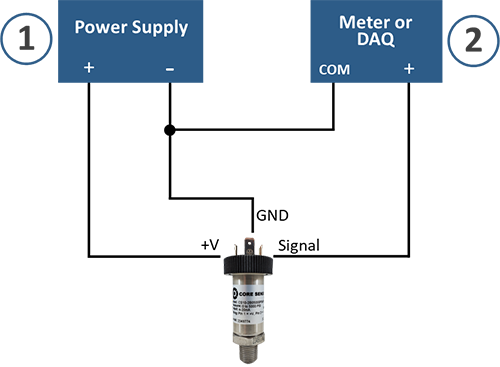

3-Wire Voltage Wiring Schematic

How To Guide

For this how to guide, we have three components; power supply, Core Sensors pressure transducer, and a meter or other DAQ system.

1) Power Supply – Connect the positive (+) terminal of the power supply to the +V pin or wire of the transducer. Connect the negative (-) terminal of the power supply to both the Ground (GND) pin or wire of the transducer and the Common (COM) terminal of the meter or DAQ. If using a bench test setup, this is commonly done by using a male to male banana plug to connect the power supply and meter and stacking a banana to alligator clip to connect the power supply to the transducer.

2) Meter or other data acquisition (DAQ) – Connect the Volts input terminal of the meter or DAQ to the Signal pin or wire of the transducer.

* In certain circumstances, there may be an additional pin or wire used as a case ground. This connection is not critical to the output signal but may be critical to maintain listed certifications of the transducer. Please refer to Core Sensors wiring guides to verify wiring prior to installation.

Advantages

- Many signal configurations to fit a variety of electronics options, power supplies and PLCs

- Low-power, low current consumption options

- “Live Zero” options improve troubleshooting support (for example, no power vs system/sensor failure)

Disadvantages

- Long cable runs can lead to signal attenuation/signal loss

- Does not have the level of noise immunity as 4-20mA current output

Common Applications

Tank Level Monitoring – For tank level applications, a voltage output pressure sensor with an IP-68 rating can be packaged with a SCADA system to remotely monitor fuel or water level for remote installations requiring low current consumption due to battery life concerns. The CS12 Submersible Pressure Transducer and CS82 Intrinsically Safe Submersible Pressure Transducers can be manufactured with a low current consumption ASIC to perform in this application.

Oil Field Equipment – In remote oilfields, voltage output pressure sensors and temperature sensors consume less battery life while providing enough signal to measure the media and transmit the signal to the telemetry unit. Data is then sent to the cloud for analysis and monitoring.

IIoT – Industrial applications continue to take advantage of IoT technology. Factories are measuring pressure and temperatures of test equipment as well as automation equipment to maximize efficiency, especially in locations where it is too costly or difficult to run power.

HVAC and Refrigeration – Voltage output signals continue to be a popular option amongst HVAC/R OEM and service installations. Due to the low cost and ease of use, pressure, temperature, and combination sensors can all be quickly integrated with noise immunity within the commonly short distances where sensors are run in HVAC automation applications, such as boiler rooms. Products such as the CS10 Industrial Pressure Transducer can be designed with a voltage output signal for low to high volume applications.